KALİTE KONTROL SÜRECİ

Üretimin her adımına entegre edilmiş bir sistem olarak kalite kontrol sürecimizi ilerletiyoruz. Tüm parçalarımız; hammadde girişinden nihai ürün sevkiyatına kadar sıkı kalite kontrol süreçlerinden geçmektedir. ISO 9001:2015 kalite yönetim sistemimiz çerçevesinde yürüttüğümüz bu süreç, hem ürün güvenliğini hem de müşteri memnuniyetini garanti altına alır. Yapılan kontroller ERP sistemimizde kayıt altına alınarak izlenebilirlik sağlanır.

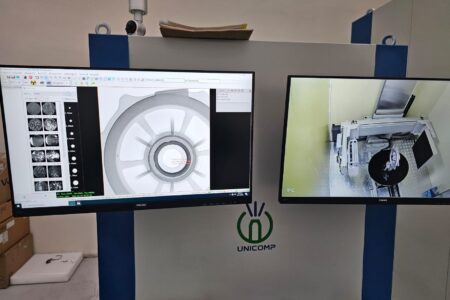

KALİTE KONTROL EKİPMANLARIMIZ

Kalite kontrol parça ölçüm ve incelemelerimizde; 3D CMM (Koordinat Ölçüm Cihazı), profil projektör, yüzey pürüzlülük ölçüm cihazı, sertlik ve çekme test cihazları, spektrometre, X-Ray ölçüm cihazı, 3D dijital ölçüm sistemleri ve mikro yapı analiz cihazı gibi yüksek hassasiyetli ve teknolojik donanımlar kullanmaktayız.